Advanced equipment and technology

Technological innovation and research and development

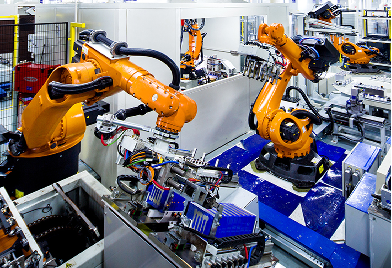

Intelligent production

Customized solutions

LISUS commenced its operation in 2010,With more than 10 years professional experience and precision machining technology to provide turnkey solutions for high-hybrid small-volume needs in the global automation, automotive, aerospace, medical and industrial markets.

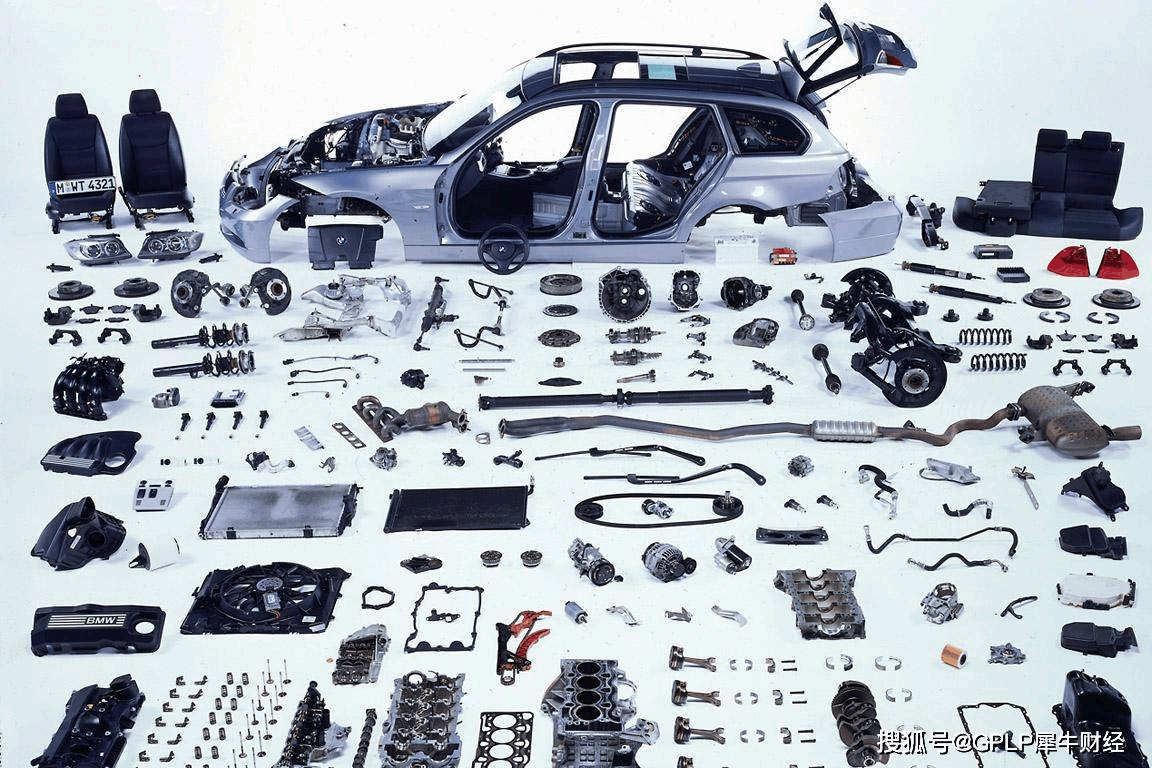

Our core business includes multi-axis machining, sheet metal machining, turning part and field of stamping parts. In addition, we provide a range of value added services such as rapid prototyping, manufacturing design, technical support and custom service capabilities to support our customers.

Our company is committed to precision manufacturing, backed by over 20 years of technical expertise and industry experience. We operate under internationally recognized standards, strictly implementing ISO 9001 and IATF 16949 quality management systems to ensure consistent excellence in every process.

With a highly skilled team of engineers and technical professionals, we combine intelligent manufacturing with rigorous quality control to deliver reliable, high-performance solutions and competitive products.

...

In the heart of the automotive industry, multi axis machining and sheet metal techniques intertwine to shape the sturdy skeleton and exquisite appearance of vehicles. The ingenuity of turning parts and the precision of stamping parts together contribute to the excellent performance of the engine and transmission system. We rely on a high-tech quality manufacturing system to ensure that every detail reaches the ultimate precision and reliability, so that every car we drive out carries the unremitting pursuit of performance and durability.

The exquisite skills in multi axis machining, sheet metal machining, turning parts, and stamping parts are accelerating the development of intelligent equipment. The innovative achievements in these fields provide stronger and more flexible "bones" and "muscles" for intelligent robots. From precision components to complex structures, our technology empowers intelligent equipment to demonstrate unprecedented precision and efficiency in various industry applications.

The advancement of multi axis machining and sheet metal technology, combined with precision manufacturing of turning and stamping parts, is profoundly promoting the leapfrog development of aerospace. We utilize cutting-edge technology to create high-strength and lightweight aviation components, from complex structural components to precision connectors, ensuring excellent performance and safety reliability of the aircraft, injecting strong innovation momentum into the aerospace field.

We are committed to precision manufacturing of medical equipment to meet the high standard needs of global medical institutions. From precision surgical instruments to complex medical equipment, our professional knowledge ensures that every product can provide excellent performance and safety.

The precision parts we produce provide stable support for electrical, telecommunications, and electronic equipment, assist in technological innovation, and ensure that the equipment exhibits excellent performance and safety in various applications.